Metal stamping and forming are the foundation of modern manufacturing. This blog will pit two...

Kryton Metals Blog

Spun to Perfection: Understanding the Power of Metal Spinning

The power of metal spinning supports traditional metal fabrication with cost-effective spin forming and fast outcomes. This technique combines artistry with engineering to render precision shapes according to complex geometries. Its origins date back centuries, but modern metal spinning tools are advanced and tailorable.

Engineers can create intricate decorative pieces, custom metal parts, and other vital components for innovation using metal spinning processes. The applications and benefits are many. We will discuss those in this blog.

Join us as we examine the power of metal spinning tools and techniques. Let’s unravel the remarkable fusion of technology and ingenuity, enabling masterpieces that are spun to perfection. We’ll explore metal spinning types, limitations, applications, and cost-effective strategies to ensure quality compliance.

What Is Metal Spinning?

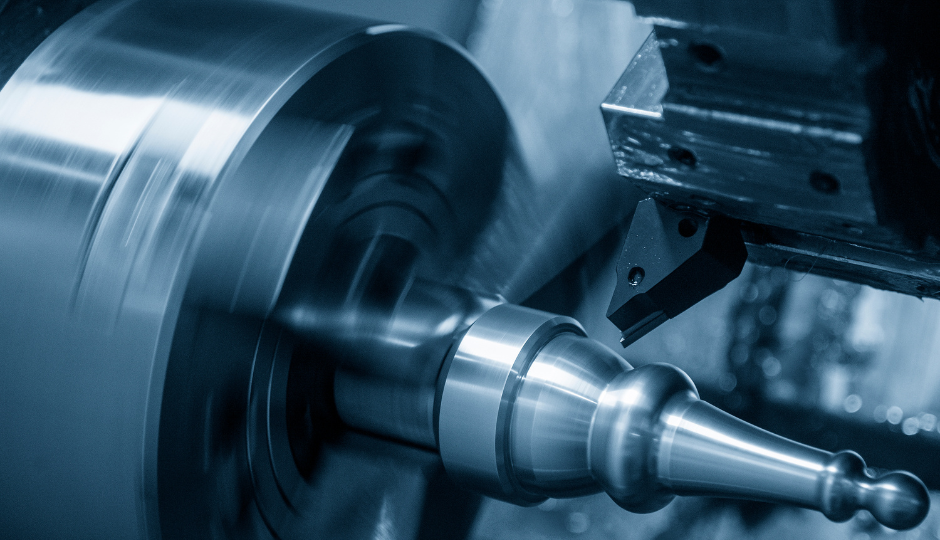

The metal spinning definition is a manufacturing process involving flat discs or sheet metal rotated on a lathe for shaping. Processes utilize mechanical force or manual hand tools to form metals into a desired shape. While the process can produce pieces with complex curvatures, it generally maintains a uniform wall thickness throughout the piece, which is determined by the thickness of the original sheet or disc.

Spun metal products have entered multiple industries, including decorative items and functional components. As a cost-effective manufacturing solution, metal spinning is ideal for creating prototypes, bespoke pieces, and also medium to large production runs of custom metal fabrications. Teams can use it to transform raw metals into distributable works of art.

Materials for Metal Spinning

After confirming the initial design, operators can secure a metal blank into a rotating spindle. They will use various hand tools and hydraulic mechanical robotics to apply force and shape the workpiece. Most processes use mandrels, rollers, or forming instruments to guide the machines.

However, metal spinning tools and techniques can depend on the material. Here are some common metals for this fabrication method:

- Aluminum

- Steel

- Stainless steel

- Brass

- Copper

- Bronze

- Titanium

- Silver

- Zinc

- Other alloys

Types of Metal Spinning

There are many different types of metal spinning techniques to consider. Let’s go over them next:

- Conventional Spinning – Metal blanks rotated on a lathe for shaping with hand tools and pressure.

- Automatic Spinning – Robotic machines with automated tooling control systems for forming various shapes.

- CNC Spinning – Computer numerical control machines automating rotating for precise repeatability.

- Incremental Spinning – Metal blanks shaped incrementally by multiple lathe processes to enhance strength.

- Hot Spinning – High temperatures improving metal ductility to form complex shapes from hardened materials.

- Flow Forming – Metal spinning and metal flow combine to fabricate intricate geometries with exceptional precision.

Metal Spinning Benefits and Limitations

Using metal spinning tools and techniques is a cost-effective approach toward consistent, high-quality metal fabrication. Teams can tailor methodologies based on project parameters, budgets, fidelity requirements, industry standards, ISO, and more.

Metal spinning services offer high precision to ensure compliance with regulations and alignment with goals. Spin forming is speedy and convenient, with multiple iterations per hour using advanced machinery.

Spun metal parts are safer to make than traditional methods because they involve automation, robotics, and computer numerical control. Operators can fabricate components, complete post-processing, evaluate quality, and prepare products for distribution with minimal risk.

Conversely, teams must recognize metal spinning limitations. Factors that can affect manufacturing capabilities include:

- Design complexity

- Metal type

- Material dimensions

- Wall thickness

- Project size

- Facility location

- Lead times

- Budget

Get a metal spinning quote to calculate costs and determine which path you want to pursue.

Metal Spinning Applications

Is spin forming the most cost-effective option? That answer depends on your desired outcome. Choosing metal spinning as your primary manufacturing method could make sense or be impractical. Let’s check out the standard applications:

- Auto parts

- Agricultural equipment

- Aerospace components

- Industrial structures

- Artistic installments

- Custom metal fabrication

Qualified professionals can help manufacturers build robust inventories of highly durable products with consistent properties. Possibilities range from fuel tanks, side panels, exhaust systems, and engine housings to irrigation systems, missile nose cones, silo components, and HVAC equipment.

Metal Spinning Tools for Cost-Effective Fabrication

Tooling selection is essential in metal spinning regardless of the chosen application. Operators must determine tolerances, geometries, material properties, and other details before fabricating tools. Those instruments shape workpieces according to the design, timeline, and budget.

Spun metal parts are efficient, but are they cost-effective? Complex designs and short lead times could cost more than simple projects and small volumes. However, many manufacturers choose metal spinning services because of the quickness, convenience, and consistency.

The decreased waste in time, labor, and materials helps cut expenditures despite the limitations. These benefits are evident throughout each phase.

Conclusion

Understanding the power of metal spinning means learning the benefits, limitations, applications, and processes. Fabricate precision parts, complete custom orders, and innovate with cost-effective design iteration. Then contact Kryton Metals when you’re ready to enhance outcomes and protect your profit margins.