Metal fabrication techniques can vary depending on the desired end product, budget restrictions,...

Kryton Metals Blog

Choosing the Best Welding for Any Metal Fabrication Project

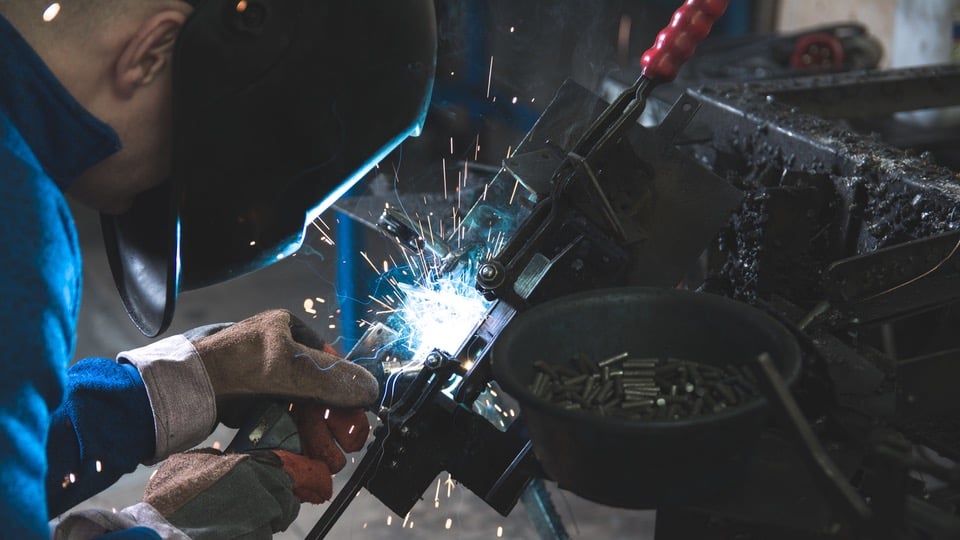

Welders can complete a variety of metal fabrication orders with consistent precision by applying high heat. During the welding process, the intense heat temporarily transforms rigid materials into a molten or semi-molten state, allowing for strong bonding between the pieces. Each welding method requires different tools and techniques.

Since the Middle Ages, fabrication shops have been producing steel welded components. Back then, parts were heated over an open flame before being hammered together. But we have more sophisticated methods today. As a result, tailored projects are more manageable, and we now have various techniques to get the job done.

DID YOU KNOW: There are various types of welding, including several that utilize electricity, such as arc welding, and others that employ lasers, like laser beam welding.

Common Welding Types

The most common welding type is MIG welding, or gas metal arc welding (GMAW). This technique employs a wire electrode and shielding gas to generate heat and join materials. It typically requires a constant voltage supplied by a direct-current power source. While MIG methods are suitable for industrial welding projects, they may not work for everything.

Other types of welding include:

- Flux Welding - Flux-Cored Arc Welding (FCAW)

- TIG Welding - Gas Tungsten Arc Welding (GTAW)

- Stick Welding - Shielded Metal Arc Welding (SMAW)

Metal welding projects require different techniques depending on several factors, including the materials and design. However, the best welding methods can provide innumerable value-adds to any facility. Clients also benefit from reliable metal fabrication, manufacturing, and assembly.

Welded steel, aluminum, and other materials are vital to countless industries. Welders join components to build everything from skyscrapers and auto parts to medical tools and HVAC systems. As a result, welding services are usually paramount in construction, technology development, and metal fabrication.

How Welding Benefits Metal Fabrication Projects

Welding services typically go hand-in-hand with metal fabricating. That’s because welded products provide several advantages to the fab shops that create them. Here are three examples:

#1. Quality Welds Offer Project Versatility

Virtually every industry requires welded parts at some point. So, metal fabrication shops that offer welding services can provide more versatile design options. One-stop service providers in metal fabrication can handle various tasks such as cutting, bending, and assembly in addition to welding. This comprehensive approach streamlines the manufacturing process, saving time and resources for clients across industries.

#2. Welding Increases Design Permanence

Welding achieves design permanence by creating a fusion between materials at the molecular level, which ensures a stronger connection than other methods. This inherent strength contributes to the overall structural integrity and reliability of the final product, even under demanding conditions.

#3. Optimize Costs with the Best Welding Services

Welders can complete projects at varying price points based on design specifications, offering cost-effective solutions compared to certain other manufacturing processes. However, it is essential to choose the most suitable welding method to ensure cost optimization.

Experienced operators can perform welds efficiently, potentially reducing fabrication costs and lead times. Knowledgeable experts can explain how the appropriate bonding methods benefit metal fabrication projects while also describing the differences between metal welding and metal fabrication. Don't hesitate to ask questions to ensure you're making the most informed decisions for your project.

FACT: KRYTON Engineered Metals frequently fortifies metal spinning and cutting with high-speed welding services.

The Differences Between Metal Fabrication and Welding

Metals play a crucial role in the modern world, and companies that specialize in manufacturing or assembling metals contribute significantly to our economy. It's important to note that metal fabrication and metal welding are distinct processes, even though they are often used together. These are the key differences:

1. Fabrication Encompasses a Variety of Techniques

Metal fabrication encompasses various methodologies, including spinning, metal forming (brake press work), and welding. While welding is specifically focused on joining two pieces together, it is one of the many techniques within the broader process of metal fabrication. In this context, think of fabrication as a holistic process, with welding being an integral part of it.

Fab shops start with a design for engineers to build, which is referred to as fabrication, manufacturing, or assembly. Depending on the specific requirements of a project, the design and build process may include welding services or not involve any soldering at all.

2. Both Operations Require Unique Tools

Fabricated metals typically undergo specific processes, such as cutting, milling, bending, or machining. Metal fabrication involves cutting sheet metal to achieve precise dimensions. So, fabrication shops use shears, saws, lasers, and other machines to complete orders.

Welding projects utilize specialized tools to generate heat, allowing for the fusion of raw materials during the joining process. That means welders manage torches, clamps, consumable electrodes, and other resources. Plus, metal welding can be dangerous, and operators must follow strict safety guidelines from start to finish.

3. Welding and Fabrication Take Distinct Skills

Metal fabrication and welding both use specialized tools to complete the desired task. But that doesn’t mean the processes require similar skills. On the other hand, welders often perform the joining process manually, even though some welding techniques may incorporate automation.

Both operations require skilled tradespeople with several years of experience. Many facilities employ both machining and welding experts to accommodate a wide range of services. However, not all fabrication shops have the capabilities to handle both processes. Some may specialize in metal fabrication without offering welding services, while others might focus on welding without providing comprehensive fabrication solutions.

Choose the Best Welding for Any Metalworking Task

Selecting the most advantageous machining, manufacturing, or welding services can be challenging, and your project might require additional steps. However, KRYTON Engineered Metals recognizes that welding is an integral part of the metal fabrication process. Our experts are well-versed in both metal fabrication and welding techniques, enabling them to help you choose the best approach for any project.

Reach out to our team for more information. We provide details about our services and the markets served, and we give fast quotes to those who request them. Determine your project parameters and stay within the budget with us.