Laser cutting plays a crucial role in the ever-evolving manufacturing industry. As innovative ideas...

Kryton Metals Blog

Advantages of Fiber Laser Cutting Systems

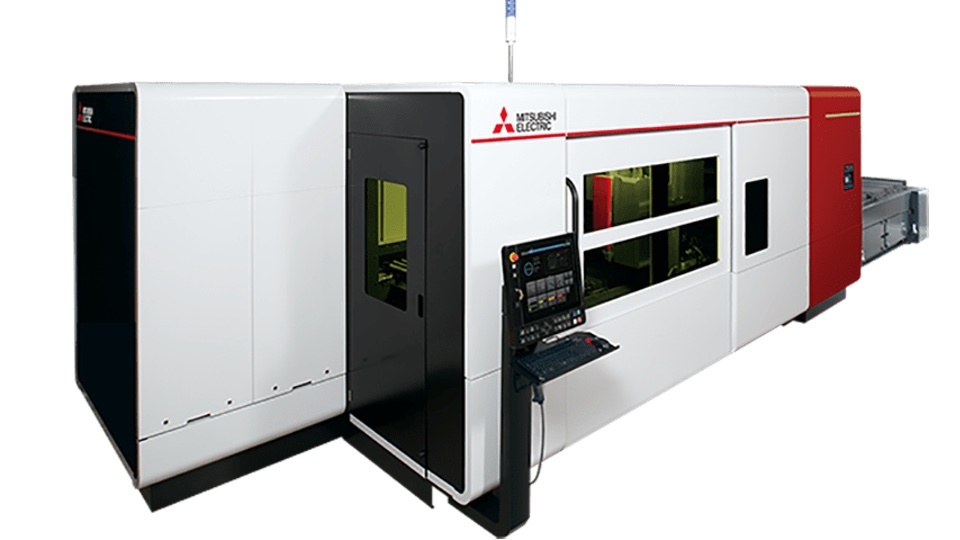

Fiber lasers are integral to a high-tech metal fabrication shop, assisting engineers in executing complex designs with exceptional precision and speed. Given the fast-evolving landscape of laser technology, it is crucial to continuously explore and adapt new advancements to optimize productivity, efficiency, and cost-effectiveness.

Advanced fiber laser cutting technologies are increasingly becoming a staple in modern manufacturing. Manufacturers frequently use them to meet crucial goals and remain competitive in fast-paced markets. Historically, CO₂ lasers revolutionized the metal fabrication industry, supporting innovation and large-scale production. However, fiber lasers, with their distinct advantages, are continuing to push the boundaries of this industry—both techniques have pros and cons.

Here’s what you need to know about the new era of laser systems.

Fiber Lasers vs CO2 Lasers: Which Is Better?

Fiber lasers and CO₂ lasers use different sources of power and energy. They also operate at different wavelengths. The variables can dictate which designs your team can fabricate and which materials they can use. Let’s talk more about the advantages and disadvantages of each.

CO₂ Laser Cutter

Advantages:

- Efficient at cutting and engraving non-metallic materials and certain types of plastics.

- Better suited for cutting thicker materials.

- Often less expensive to purchase initially.

- Can be more effective for thicker materials and applications requiring a larger focal point.

- Has been a trusted technology in the industry for many years.

Disadvantages:

- Less effective at cutting and engraving metals.

- Requires a longer warm-up time.

- Maintenance can be more time-consuming and costly. This includes the need to replace gas tubes periodically.

- Uses more power and hence less energy efficient.

Fiber Laser Cutter

Advantages:

- Very efficient at cutting and engraving metals.

- Typically more energy-efficient, leading to lower operating costs over time.

- Requires less maintenance (e.g., no need for mirror alignment, no consumable parts).

- Shorter warm-up time.

- Smaller size and weight due to solid-state design.

- More suitable for cutting thin materials and achieving high precision.

Disadvantages:

- Typically more expensive to purchase initially.

- Can be less effective for cutting very thick materials.

Each of these technologies has its place in the industry and the choice between a CO₂ laser cutter and a fiber laser cutter will depend on the specific needs and other factors.

TIP: Talk to your team about the best techniques, or consider other CNC machining methods to complete challenging orders.

How Versatile Laser Systems Benefit Metal Manufacturers

Metal fabrication is a dynamic field that fosters creativity and innovation across various sectors. Manufacturing facilities must continually adapt and expand their service portfolio to accommodate a range of innovative projects. Although our shop specializes in fiber laser cutting technology, we strive to fully utilize its advantages, enabling us to meet diverse customer requirements.

This state-of-the-art technology excels in precision work and metal cutting, giving us a competitive edge. While we recognize the potential benefits of having different types of laser systems, such as CO₂ lasers, we are committed to leveraging the strengths of our available resources. By doing so, we aim to provide top-tier services that meet the needs of our customers, and we continually assess our capabilities against these needs to ensure that we offer the most efficient and effective solutions possible.

Offering a versatile playbook can help metal fabricators and their clients in several ways, including these:

Enhanced Part Fidelity

Options mean choosing the variables that suit your goals. Advanced laser systems and services can support unique concepts and help disrupt the market flow without ignoring industry standards. Produce parts with better fidelity using whichever laser system makes the most sense.

More Efficient Prototyping

Creating prototypes allows teams to determine specific elements of a design. However, functional prototypes and assemblies for demonstration might require additional manufacturing processes. These processes, while potentially increasing production time and costs, are invaluable in uncovering design flaws and optimization opportunities before the full-scale production commences.

Order Customization

CO₂ laser systems and fiber lasers enable a high degree of customization and efficiency in metal fabrication. These systems are typically faster than traditional manufacturing techniques and can significantly reduce production lead times. Their precision makes them well-suited for fulfilling small batch orders efficiently and accurately. Additionally, many modern laser cutting machines are designed to minimize waste during operation.

Metal fabrication facilities that offer services with both CO₂ and fiber lasers may cater to a wider range of customer needs, which can potentially enhance profitability. However, it's crucial to understand that the choice between these laser systems should be made based on project requirements, as each has distinct pros and cons. Discussing these options with your team can help determine the most suitable approach for any given project.

Fiber lasers revolutionized metal fabrication by adding speed and efficiency to the process. Meanwhile, high-pressure CO2 lasers offer different and equally essential benefits. Learn which one to choose by considering the pros and cons. You can use both services to develop unique products ahead of your competitors.

Reach out to a fiber optics expert at KRYTON Engineered Metals for more information or to launch a new project. Discover the possibilities of fiber lasers and CO2 laser cutters to determine your best bet. Ask for an estimate to get started, and then submit your designs to begin innovating with purpose.