Agricultural metal fabrication supplies numerous vendors with manufactured parts, playing a vital...

Kryton Metals Blog

How the Food Industry Relies on Metal Fabrication

The food and beverage industry heavily depends on high-quality sheet metal fabrication to produce safe and standardized goods. Some food processing facilities require consistent laser-cutting services and top-grade stainless steel to deliver premium end-use products. Engineered metals are a fundamental component in everything from food storage equipment and resealable containers to prep tables and utensils.

Without efficient metal fabrication processes, many popular restaurants might find it difficult to meet consumer demands. Similarly, grocery stores, gas stations, and other businesses could face challenges such as non-compliance with industry regulations, which could lead to fines and penalties. The use of stainless steel, rapid prototyping, and precision CNC machining is indispensable in today’s food and beverage industry.

Are you curious about how metal fabrication aids in supporting global food production and distribution? This article will explore the various benefits of high-precision manufacturing for food processing. Talk to a metal engineering expert for more personalized information.

Benefits of Metal Fabrication for Food Production

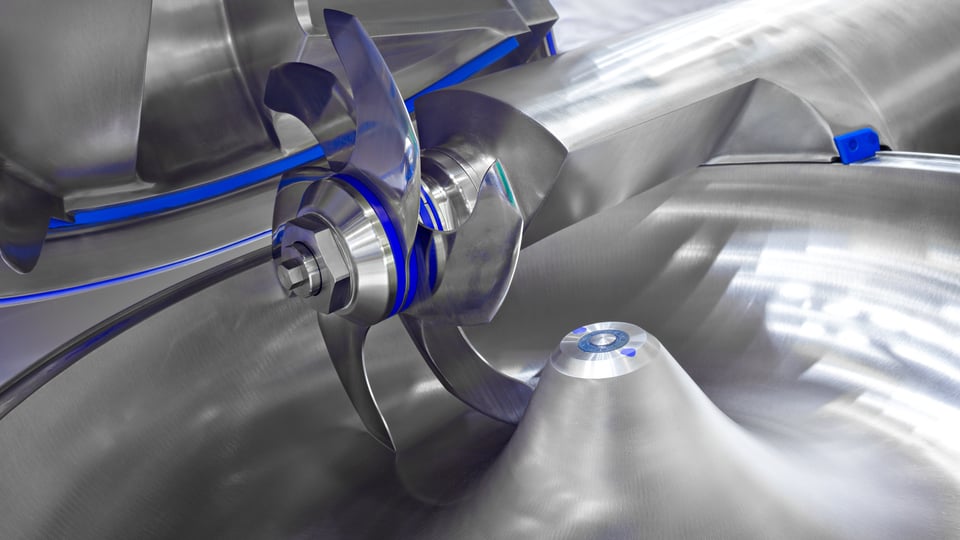

Equipment used in food processing must maintain sterile conditions, with some components requiring an airtight design. Additionally, food producers and distributors necessitate storage containers robust enough to endure transportation across diverse climates. Preferred materials in much of the food and beverage industry are aluminum and stainless steel, both of which must be accurately fabricated to meet certain specifications.

The fabrication processes allow engineers to develop more durable storage solutions and better food preparation equipment. This not only enhances productivity but also reduces waste and minimizes manufacturing costs, making it an invaluable part of the food and beverage industry. Here are a few more advantages to consider:

Cost-Effective Product Prototypes

Rapid prototyping (RP) and additive manufacturing (3D printing) let teams innovate without compromising on quality or extending lead times. These methodologies can expose design flaws before mass fabrication and distribution, ensuring compliance with stringent standards in the food and beverage industry. With custom machining and a variety of metal fabrication techniques, producers can bring revolutionary food products to both new and existing markets.

DID YOU KNOW? Rapid Prototyping can be utilized to test and evaluate a variety of design concepts before selecting the optimal solution.

Improved Product Inventories

Businesses within the food and beverage industry tirelessly strive to deliver products that taste great and retain freshness. However, traditional metal fabrication techniques may not always suffice to meet regulatory requirements. Combining rapid prototyping with custom machining not only sparks innovation but also ensures adherence to strict guidelines.

DID YOU KNOW? Supermarkets, which stock large inventories of edible products, comprise the largest share of the food and beverage market.

Delighted Consumers

Consumers in the food and beverage sector won’t compromise on quality. They insist on freshness, convenience, and value for money. However, advanced metal fabrication services can come with a substantial price tag. Custom machining tailored for food-grade components is indispensable in managing the global economic implications of food production and distribution. This enables manufacturers to meet or even surpass industry expectations without exceeding their budgets.

DID YOU KNOW? On average, Americans spend about 12% of their household income on food.

Enhanced Production Quality

Creating better products equates to generating higher revenue – a fundamental principle of supply and demand. It’s not necessary to increase your product prices to enhance profitability. Exceptional engineering and fabrication of metals specifically for food processing can yield a multitude of benefits. This includes gaining consumer trust, ensuring retail outlets are eager to stock your products, and helping your company avoid issues such as product recalls, liabilities, and legal disputes.

DID YOU KNOW? The USDA tracks the number of food poisoning cases based on specific criteria, including food types, health outcomes, and jury awards.

As a member of the food and beverage industry, your fundamental responsibility is to provide safe, practical, and competitively priced products. Using high-precision metal fabrication techniques is an effective way to fulfill this duty. The use of advanced methods in metal fabrication can foster innovation while keeping costs under control.

What Can the Food and Beverage Industry Do with Better Fabrication Projects?

Metal fabrication plays a large role in helping producers maintain healthier inventories and exceed market expectations. Techniques like laser cutting can precisely machine highly durable stainless steel, ensuring impressive precision and consistent quality This process enables you to prepare, treat, and coat food processing products, guaranteeing that your food-grade items not only look appealing but also perform optimally.

Talk to an engineered metals expert for detailed information and to create a manufacturing strategy that suits your objectives. The choice of your metal fabrication team significantly influences the final product’s quality.

The food and beverage industry is responsible for a substantial portion of the world’s consumable products. As a result, manufacturers and food processing plants are subject to strict industry standards to safeguard public health and safety. High-quality metal fabrication plays a key role in ensuring compliance with these standardized methodologies, offering both precision and speed.

To stay up to date on what you need to know about metal fabrication in your industry, subscribe to the KRYTON Metals Blog.