In the world of construction and engineering, choosing the right metal for projects in harsh...

Kryton Metals Blog

How to Pick the Right Fasteners for Your Sheet Metal Project

When it comes to sheet metal projects, choosing the right fasteners can make all the difference in the world between success and failure. The fasteners that you select don’t just hold a couple pieces of sheet metal together—they directly impact the functionality, durability, and ease of assembly of your finished product.

Whether you’re working on a large industrial application or a small-scale prototype, the right choice of fasteners will make sure that your project can withstand the test of time and perform as expected in its specific environment.

FACTORS TO CONSIDER WHEN CHOOSING FASTENERS

When choosing fasteners for sheet metal projects, several key factors come into play. Material compatibility is crucial—using hardware that matches or complements the sheet metal helps prevent corrosion and maintains structural integrity.

For example, using aluminum fasteners with carbon steel sheet metal or vice versa marginally increases the chances for galvanic corrosion to occur. The best practice is to use fasteners made of the same material as the panel you’re fastening to.

Real life example: In 2013, Ford made the switch to aluminum body panels, and a federal judge allowed a class action lawsuit to proceed, stating that Ford failed to properly insulate the aluminum hoods from iron parts, leading to galvanic corrosion and financial losses for owners.

Next, consider the strength requirements of your project. For example, PEM nuts are great for providing load-bearing threads, while weld studs offer exceptional strength for heavy-duty applications.

Finally, environmental conditions like humidity, extreme temperatures, or chemical exposure can impact the longevity and performance of your fasteners. Opting for corrosion-resistant materials such as stainless steel or galvanized steel may be necessary in harsh environments to ensure durability.

COMMON FASTENER OPTIONS FOR SHEET METAL

When working on sheet metal projects, selecting the right fasteners can make all the difference in functionality and ease of assembly. Let’s talk about some of the most common fastener options that are readily available for sheet metal projects:

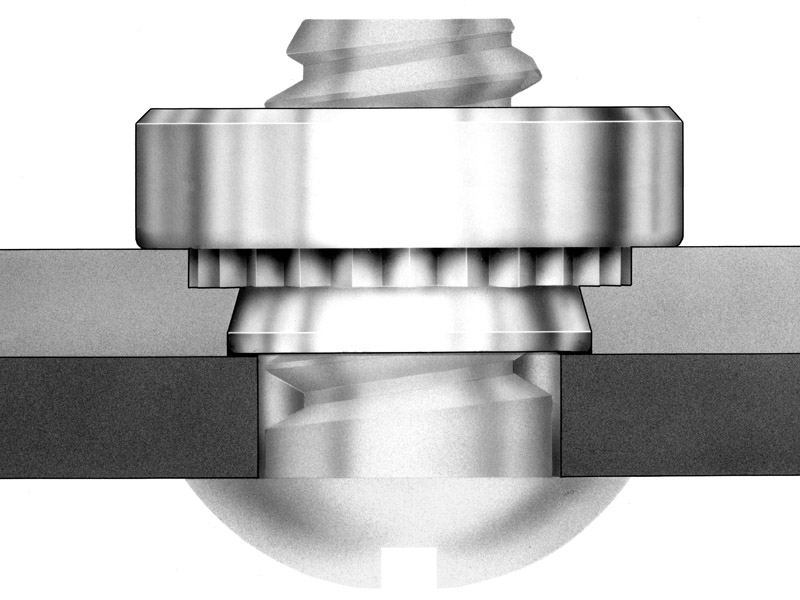

- PEM Nuts: PEM nuts are used for strong, permanent threads in thin metal without adding a bulk in your sheet—ideal where traditional threading might not be an option due to the thin material thickness.

- Standoffs: Designed to create space between parts, standoffs are perfect for mounting and aligning components in electronics or structural assemblies.

- Panel Fasteners: Panel fasteners allow for easy access to panels and doors—used when removing and reinstalling of a panel is necessary, providing a quick and easy way to secure access points without sacrificing durability.

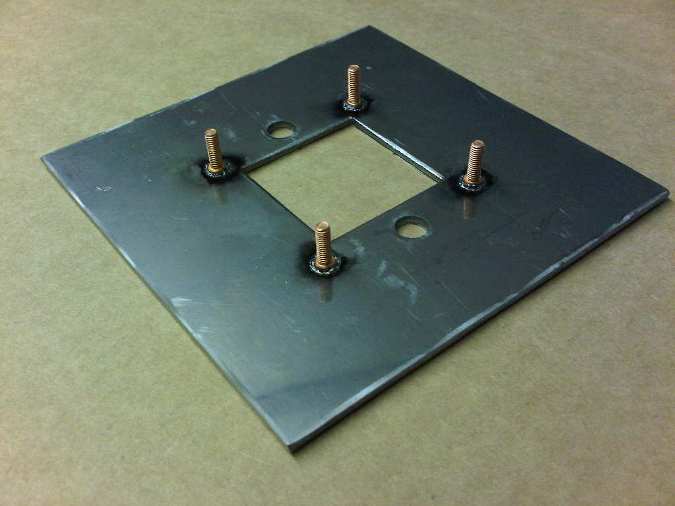

- Weld Studs: Weld studs are a high-strength, durable solution for metal-to-metal fastening. They are welded directly to the sheet metal, making them a great choice when strength and durability are critical, especially in load-bearing applications.

- Rivet: A staple in sheet metal projects, rivets are highly versatile and provide permanent, strong fastening. They work well for joining different materials and offer consistent reliability in both heavy-duty and light applications.

- Rivnuts: Rivet nuts, or Rivnuts, provide a threaded insert that can be installed into thin sheet metal using a hand tool, allowing for easy attachment of components without the need for welding.

- Weld Nuts: Weld nuts are nuts permanently attached to the base material through welding, providing a reliable threaded fastening point where durability is needed.

Some facilities don’t have welding capabilities, so weld studs and weld nuts aren’t always an option. Those that do have access to welding typically either spot-weld or MIG/TIG-weld the fasteners on their sheet metal for a high-strength connection.

MATCHING FASTENERS TO YOUR PROJECT NEEDS

A great place to start looking for the best fasteners to match your project’s needs would be to assess key factors such as load-bearing requirements, making sure that your fasteners and any other hardware can handle the stress and weight of the application.

Another thing to consider would be assembly methods—whether you need permanent fastening like rivets or removable options like panel fasteners. Additionally, the ease of maintenance should help guide your choice, especially if you’re frequently having to disassemble.

Consulting with a metal fabrication expert, such as KRYTON Engineered Metals, can help you make the right decisions, ensuring that your fasteners are compatible with the materials, environment, and functional needs of your project. The right guidance can save time, reduce costs, and improve overall performance.

WRAPPING UP

Choosing the right fasteners is important for the success, durability, and functionality of any sheet metal project. By carefully considering factors like material compatibility, strength requirements, and environmental conditions, you can make sure that your fasteners not only satisfies the demand of your project but also enhances its overall performance.

To learn more about what’s needed for your specific needs, contact us today to discover how we can help you choose the best fasteners for your sheet metal project!